Page 1 of 1

2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 3:25 pm

by dcarver

2019-08-16 KrZy8 Engine Autopsy Results

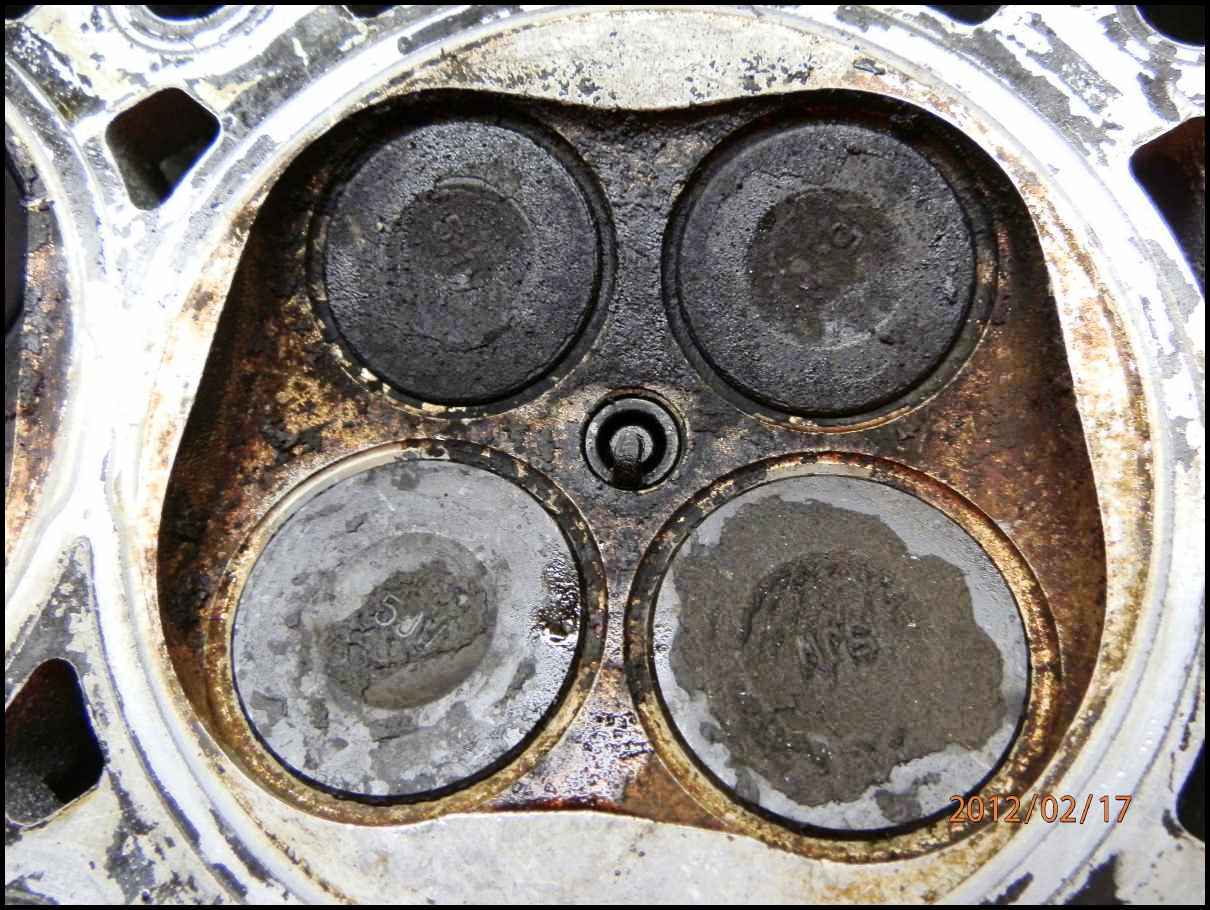

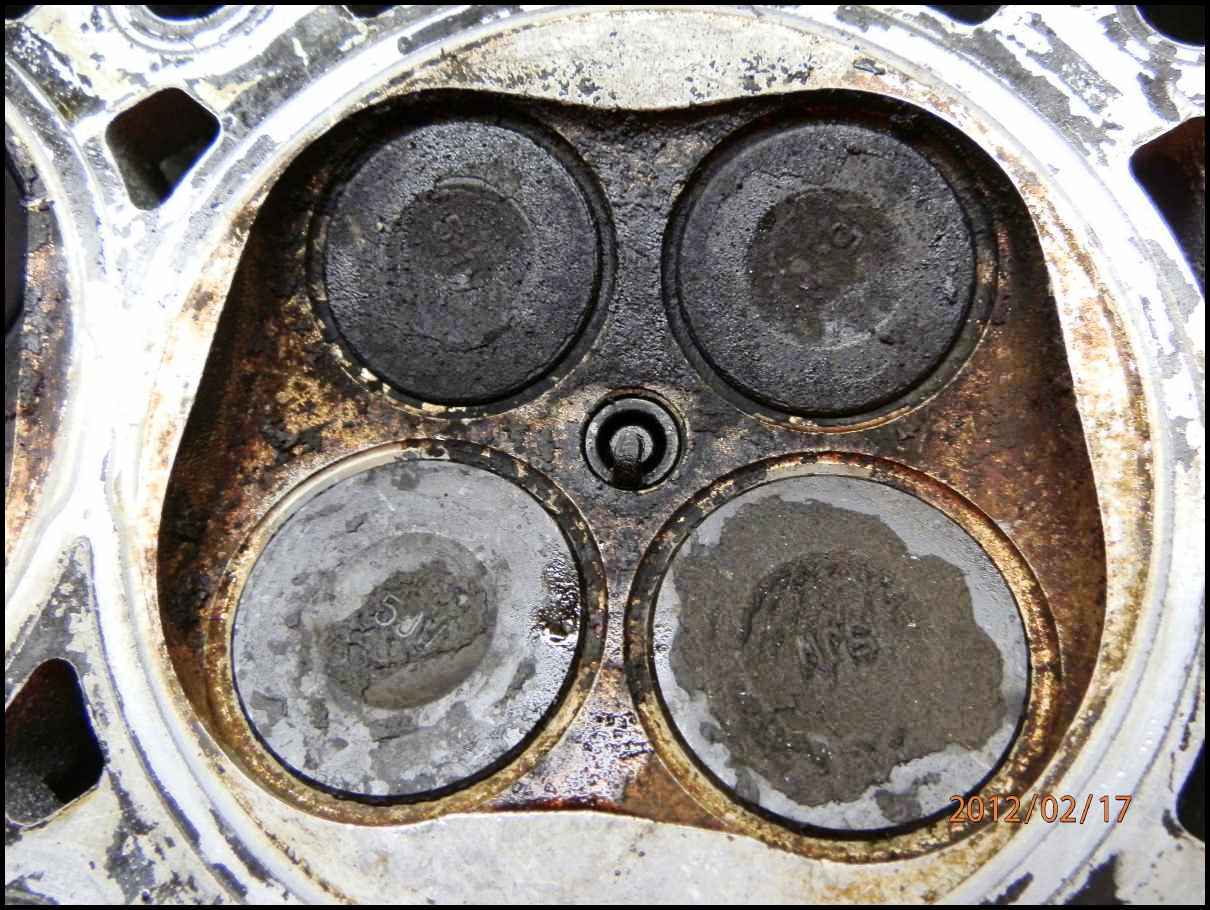

Over 7 years ago, the OEM engine was replaced. Water in cylinder. Assumed it was the head. Gave engine to FjRay to autopsy. N20sx, Carlo, needed gearbox parts. Ray gave engine to Carlo who found this..

https://candybuttorg.ipage.com/cba/node/768

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 3:51 pm

by bungie4

Holy hell that'll do it for sure. Doesn't look like a dirt issue, that looks like a liner/sleeve fail. Q: is what caused it.

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 4:02 pm

by jwilly

That will buff right out...

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 4:14 pm

by ionbeam

I have seen one other cylinder liner failure for sure and someplace in the fuzzy past I'm pretty sure I saw a second one. Not common though. Except for dcarver, the Prince of Weird Karma.

The cylinder block has circular, plane recesses, called flange seats or counterbores. These hold the cylinder liners in the cylinder block. The flange of a cylinder liner must fit exactly into such a recess, so that the liner rests on its entire circumference on the flange seat. The cylinder head gasket is then placed on the cylinder block.

When the bolts are tightened, the cylinder head is pressed firmly against the cylinder block. The cylinder head bolts and the tightening instructions are designed to achieve a firm connection between the cylinder head and the cylinder block. This means that enormous forces are introduced from the bolts via the gaskets to the liner flange. This makes it even more important that the forces via the head gasket are transmitted vertically to the liner flange.

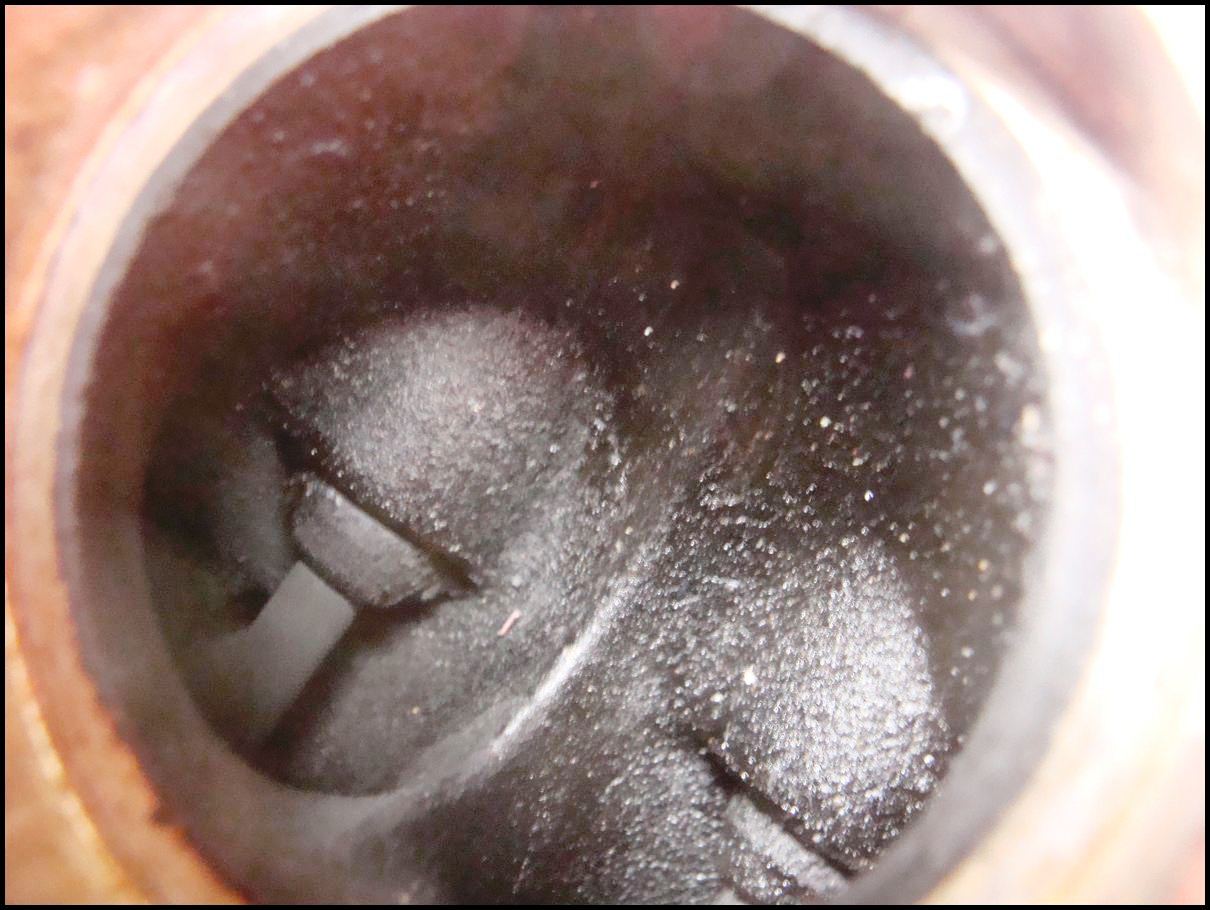

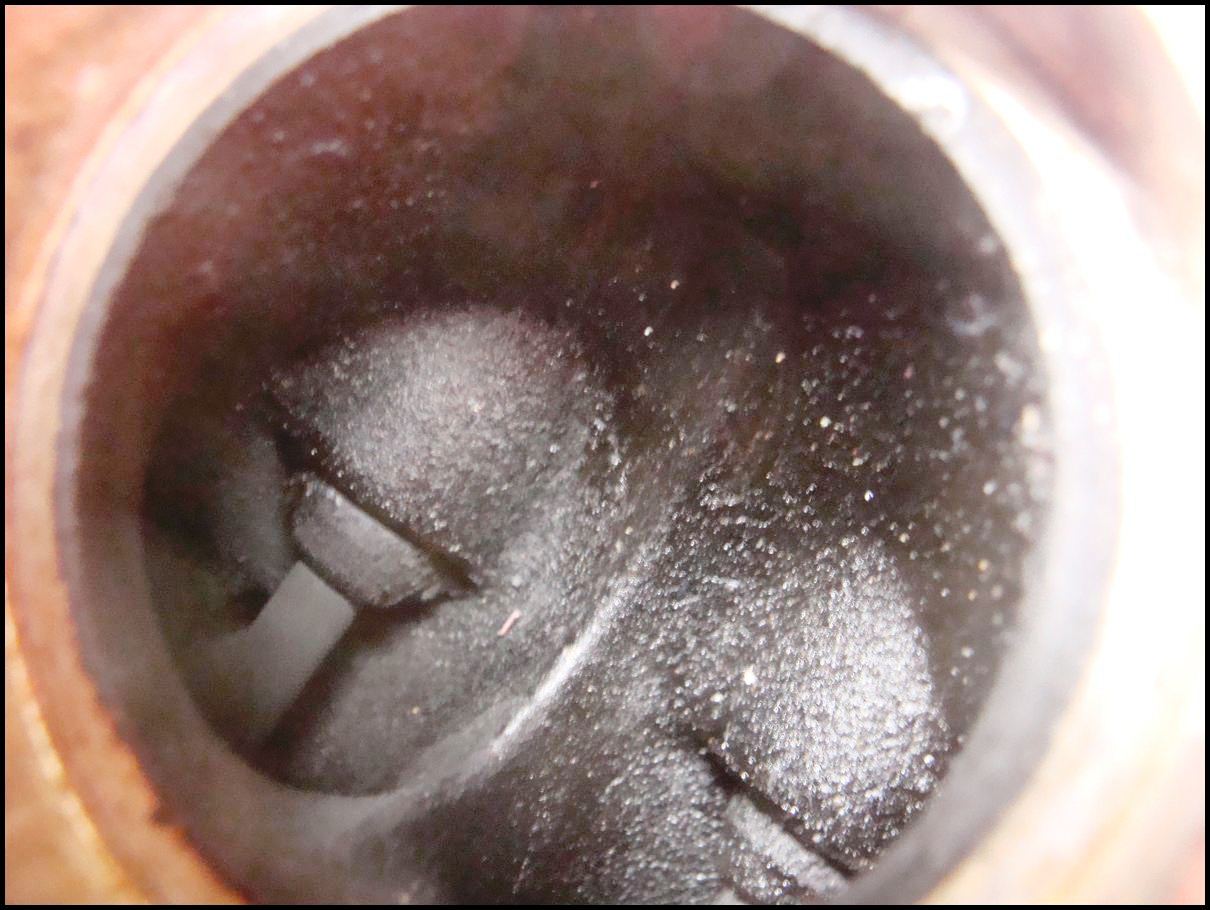

Uneven surfaces and warpage at the flange seat of the cylinder block can cause the liner to fracture. The underlying reasons for this is increasingly lighter engine designs. The warpage at the component will be worse, the thinner the wall thickness of the block. At the same time, power output, combustion pressures and torques are rising in modern engines. In engines that have been running for 350,000 miles (or the equivalent in running time) warpage can be excessive enough that the seat in the block should be re-machined. While dcarver hasn't been running his bike that long, his engine had been sucking dirt, gravel and water. If something hard got trapped between the piston and cylinder wall (sitting on the top ring) and ground away at the liner it would explain the failure. Note that the failure happened at the liner flange seat and fractured down the cylinder wall (note the splits at the bottom of the fracture). If the metal bits were not in the cylinder it means that the piston hammered them to dust on the cylinder head until the pieces were small enough to get past the valves.

It will never happen that way in a Gen III engine...

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 4:19 pm

by wheatonFJR

What kinda sounds did it make when it stopped working?

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 4:24 pm

by ionbeam

wheatonFJR wrote: ↑Fri Aug 16, 2019 4:19 pm

What kinda sounds did it make when it stopped working?

Probably none. When my Gen I bent valves and split the cylinder head it made no noise at all, there was perhaps one tiny vibration in the frame, but no noise. As I was expecting a normal start I wasn't really listening or feeling for anything wrong.

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 5:45 pm

by dcarver

ionbeam wrote: ↑Fri Aug 16, 2019 4:24 pm

wheatonFJR wrote: ↑Fri Aug 16, 2019 4:19 pm

What kinda sounds did it make when it stopped working?

Probably none. When my Gen I bent valves and split the cylinder head it made no noise at all, there was perhaps one tiny vibration in the frame, but no noise. As I was expecting a normal start I wasn't really listening or feeling for anything wrong.

Engine was still running when we removed head looking for head gasket leakage. Not running great, but running. I rode 90 miles the day before she was loaded on a trailer and taken to Hal Rissers' house.

https://candybuttorg.ipage.com/cba/node/221

Luck of the draw, piston 1 @ TDC so we didn't see the damage.

Valves for cylinder 1... No damage visible.

Wet and gooie from water intrusion. #1.

Got her all back together - filled with distilled water.

Started to do a compression check - threaded into #4 - key on - hit the starter button -

and #1 spouted like a grey whale.

The head apparently is cracked - most likely an internal cooling passage. You could look down the plug hole with a flashlight and see water slowly filling the cylinder. Or perhaps the block. No visible evidence of a crack when we had the head off.

We were about 30 minutes away from starting her up.

Compression readings -

#1 - 40 psi

#2 - 150 psi

#3 - 150 psi

#4 - 70-90 psi.

Krzy8 is on her way back to the Honderosa - strapped down in the trailer.

Full gory story here.

https://candybuttorg.ipage.com/cba/node/221

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 5:48 pm

by dcarver

If something hard got trapped between the piston and cylinder wall (sitting on the top ring) and ground away at the liner it would explain the failure. Note that the failure happened at the liner flange seat and fractured down the cylinder wall (note the splits at the bottom of the fracture). If the metal bits were not in the cylinder it means that the piston hammered them to dust on the cylinder head until the pieces were small enough to get past the valves.

Yet no real piston crown scarring or valve damage. I always use a magnet to check ferrous material when changing oil. Also inspect for shiny particulate matter.. Nothing observed.

At least her gearbox will be put to good use for a fellow FJR Rider!

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 5:53 pm

by ionbeam

dcarver wrote: ↑Fri Aug 16, 2019 5:48 pm

...no real piston crown scarring or valve damage. I always use a magnet to check ferrous material when changing oil...

I'd kinda expect that from an aluminum engine

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Fri Aug 16, 2019 6:34 pm

by dcarver

ionbeam wrote: ↑Fri Aug 16, 2019 5:53 pm

dcarver wrote: ↑Fri Aug 16, 2019 5:48 pm

...no real piston crown scarring or valve damage. I always use a magnet to check ferrous material when changing oil...

I'd kinda expect that from an aluminum engine

Gearbox full of steel. Cam lobes, chain. Lots of ferrous!

Re: 2019-08-16 KrZy8 Engine Autopsy Results

Posted: Sat Aug 17, 2019 9:37 am

by bungie4

Always insightful listening to the 'beam.