Today attempted install - epic fail.

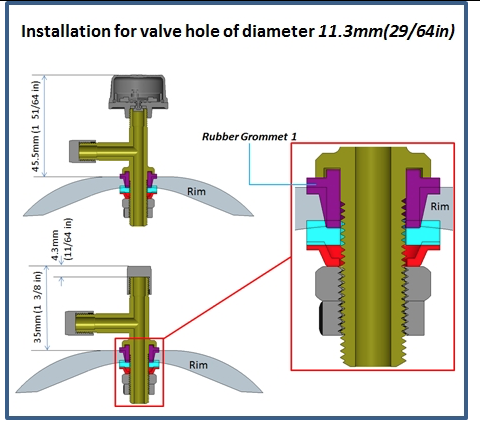

Here's how FOBO says they install...

Problem is that the rim ID is 9.4mm and the widest point, OD, of 'Rubber Grommet 1' (RG1) is 14 mm.

No way does the threaded portion of the valve stem pass through RG1 without splaying too far out, preventing even partial insertion into rim hole.

Interestingly enough, RG1 fits better when inserted upside down, e.g. 'backwards' from inside of rim poking up to the outside world.

So I gave up and used a new 90 degree metal stem instead of the trick T-Stem.

Has anyone had success with FOBO T-stem?

If so, what am I missing?